The Owner-Built Log House * Log Construction Manual

Premium log fitting

Log homes are fashionable. You can order one pre-manufactured from a catalog. Or you can make your own crude log shell for under $5,000 (see the previously reviewed How to Build This Log Cabin for $3,000).

Log homes are fashionable. You can order one pre-manufactured from a catalog. Or you can make your own crude log shell for under $5,000 (see the previously reviewed How to Build This Log Cabin for $3,000).

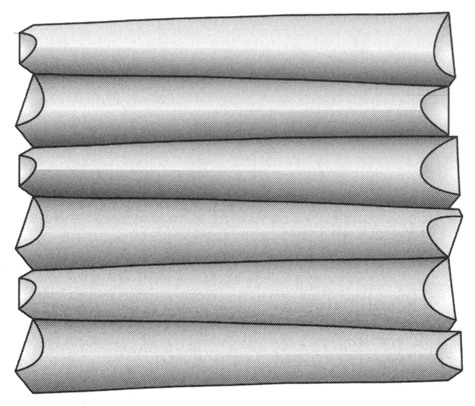

Or you can use the system featured in these books to make a log home so finely crafted that it is more like living in a gigantic piece of dove-tailed furniture. Called scribed-fit, this method produces handcrafted joints thinner than a piece of paper. You won’t save any money this way, but you’ll live in hand-made shelter of utmost craftsmanship. That joy can be worth the trouble.

And trouble it is. Building with logs this way is similar to post-and-beam construction: the scale and details are beyond a single individual. You need a team, and you should try something small first. Your path is made much easier by either of these two books.

The Owner-Built Log House is geared to the dedicated individual willing to do as much as this hard work as they can themselves, from peeling logs, to hoisting them using pulleys, to carving notches and chinking. It presents the task of building a log house as part construction project and part lifestyle — since it will consume your life. Remember, a shell of a house is only a fraction of the work. This guide is good about detailing the ways to finish it off, and the tricks need to say, get wiring in the logs.

At the highest end of quality is Log Construction Manual, the Ferrari of log homes. These aren’t houses as much as wooden jewel boxes. Most guides are based on the personal experience of the author building their own house (see above); this one is based on the author’s experience teaching thousands of others to build theirs. You get a comprehensive course, laying out the steps, the logic of the steps, and much hard-earned wisdom anticipating your problems as you learn how to scribe-fit logs into a house. But to be honest, the precision and energy needed to build this way demands you hire contractor help. You’ll probably end up working alongside the pros, perhaps teaching them some new notching skills.

At the highest end of quality is Log Construction Manual, the Ferrari of log homes. These aren’t houses as much as wooden jewel boxes. Most guides are based on the personal experience of the author building their own house (see above); this one is based on the author’s experience teaching thousands of others to build theirs. You get a comprehensive course, laying out the steps, the logic of the steps, and much hard-earned wisdom anticipating your problems as you learn how to scribe-fit logs into a house. But to be honest, the precision and energy needed to build this way demands you hire contractor help. You’ll probably end up working alongside the pros, perhaps teaching them some new notching skills.

In many ways, building a fitted-log cabin is like building a wooden boat in your backyard. Many will begin, few will finish on their own. The magnitude of this quest should not be underestimated.

03/3/14Excerpt

From The Owner-Built Log House:

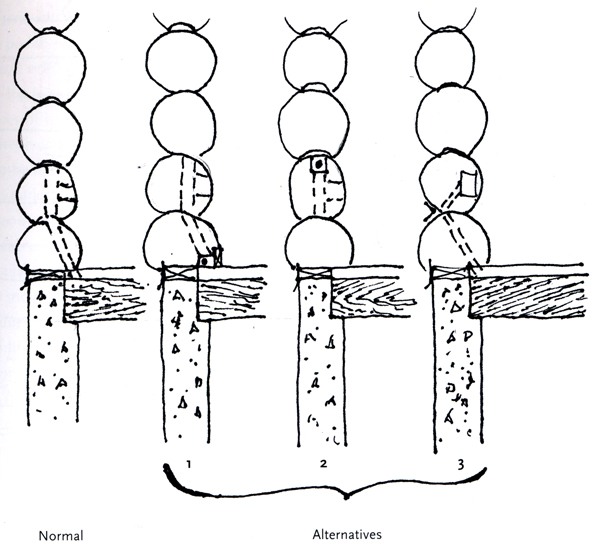

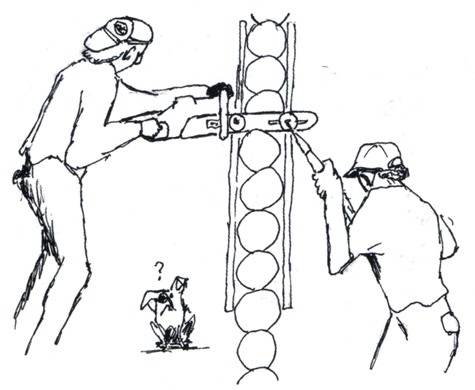

Cutting the groove while standing on the wall. You need a steady hand and a good sense of balance.

*

*

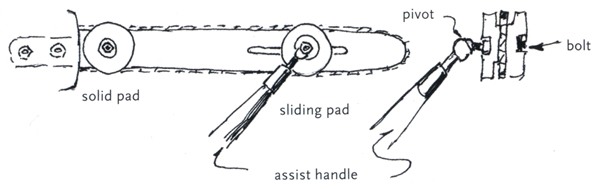

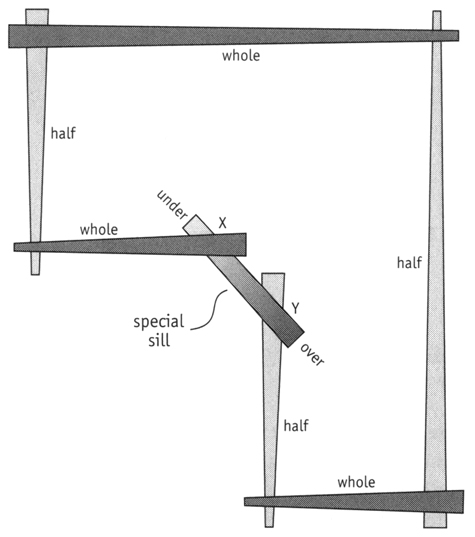

A true and accurate cut may be obtained with a chainsaw equipped with guide pads. These are now available commercially, or they can be made.

***

From Log Construction Manual:

Log Homes Don't Waste Trees

One of the most widespread and damaging myths is that log homes use extravagant amounts of wood. It does appear that "you could build a couple homes out of the logs that go into one log house," as I've heard people say. But, an average log home uses about the same volume of trees as a conventional, stickframed house of the same size.

*

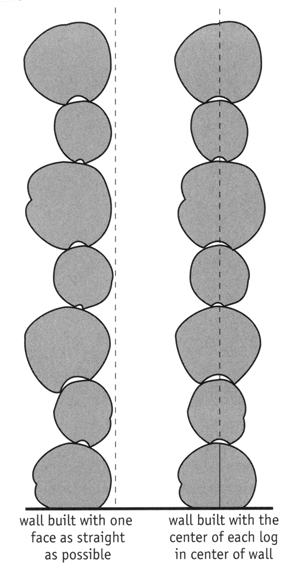

On each wall, we alternate the direction that tips and butts point every time we add another log. This helps keep walls from becoming tipped.

*

*

I recommend you build walls so that the centerline of each log is plumb above the center of the wall. Trying to make one side of a wall more or less plumb can be difficult, unattractive, and perhaps unstable.

*

A tightly-fitting round notch. Note that there are no saddles, so it is not a saddle notch.

*

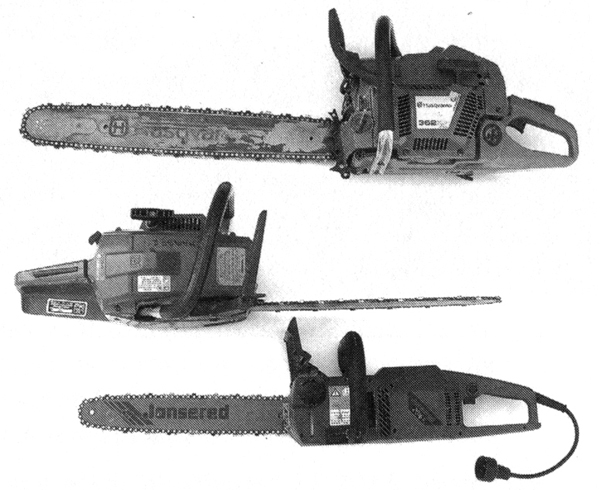

Top: Husqvarna 362XP with 24" bar.

Middle: Husqvarna 354XP with 18" bar.

Bottom: Jonsered 2016 electric with 16" bar.

I have taught more than 1000 people to cut notches, and I have seen chainsaws of almost every model, age, and condition. I'll be blunt -- an average student with a great saw does a lot better than a great student with an average saw.

Husqvarna and Stihl are the saws that I recommend. Most chain saws are not suited for log building. And, buy a professional model saw, not one designed for homeowners. Stihl and Husqvarna both have a "pro" line of saws, and you should choose from these. Expect to pay $550 to $725 USD (in 2011).

Every saw has its own feel and character. These differences are not easy for beginners to recognize, but they are real, and important. Stihls are easy to start -- when cold or hot. They have a distinctly softer suspension than Huskys -- the handles have a more flexible attachment to the motor, and the bar also has a softer connection to the motor. Stihls drive like a Cadillac. My choice for heavy ripping is a Stihl: the big Stihls (bigger than 80cc) have power, are easy to start, and have soft suspension.

Husqvarna saws are more difficult to start than Stihls, especially when they are hot. Huskys also have a harder feel to their suspension. I have more control over the bar and chain -- it's like there is a more direct link between what my hands are trying to do, and what happens. Huskys drive like a Ferrari. My choice for notching is definitely a Husky: great power-to-weight ratio, high chain speed, finesse, and superb control.

The Owner-Built Log House B. Mackie 2011, 248 pages Available from Amazon Log Construction Manual Robert Wood Chambers 2002, 272 pages Available from Amazon Book's website