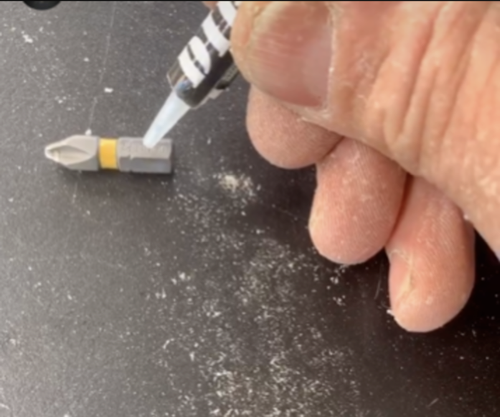

Gluing Bits?

Gareth's Tips, Tools, and Shop Tales - Issue #68

Gluing Bits?

A bit o’ CA glue’ll do.

On DiResta’s Instagram stories (which, if for no other reason, you should subscribe to his account to view), he offered this useful tip. If your bits have a tendency to fall out of their holder, dab a tiny dot of superglue on them. To debond, hit the bit with a heat gun and remove.

TOYS! Surebonder 220 Pro Glue Gun

It’s big-boned but it’s a workhorse.

Last year, after decades of dealing with cheap craft store glue guns, I decided to try a top-of-the-line industrial gun. I’m still not sure if it’s a difference worth over 100 bones, but the difference is definitely significant. I wanted a glue gun that was temperature-adjustable and heavy-duty, heated up fast, and had the precision and control that would allow me to use it on everything from small modeling projects to more demanding and large-scale projects. I did my research and the Surebonder 220 was consistently rated as the best (or among the best). It is very heavy-duty and has an adjustable temperature control from 220° F to 420° F. This allows it to use glue sticks that have a higher melting temp and better bonding strength. This review on Amazon pretty much summarizes my experience:

What an incredible difference from the entry level cheapies. Much more precise and reliable control of glue flow. Adjustable higher temp allows for use of better quality hot glue. So much better work flow than the $30 units. The price difference is justified if you do a wide range of hot glue tasks especially when high strength is required. The lower temp guns cannot utilize the higher bonding strength glues of hi temps guns. The bigger size does not mean big weight difference in lbs so size is not a big factor. There are also numerous types of tips that are available to more precisely control the glue flow if required. In this case you really get what you pay for. One good thing with the cheap gun experience is the instant appreciation that occurs when you use a professional gun.

My only con is that it is a BIG gun which makes it a bit unwieldy and it takes up a lot of benchtop space (and I like to keep it out for quick use). I’ve also heard that the bimetal thermostat can get gunky after years of use and need repair. This is easily done by opening the unit and passing a piece of paper between the contacts.

Making a Magnetic Light-Grab

Via woodmagazine.com

I just subscribed to Wood magazine (basically to mine for shop tips). Here’s a smart idea. Turning a chunk of wood and some rare earth magnets into a mount you can stick on any metallic surface to hold a clamp-on light.

Using Tool Auto Switches in the Shop

Mr. Miyagi says: Switch on, switch off.

On this Cool Tools video, Sean Ragan gathers up his sizeable collection of shop vacs(!) and decides to create dedicated tool vacuums for each machine rather than building a central dust collection system. To make this approach more workable, he installed auto switches on each tool/vac. These are current-sensing power boxes that have a plug for the tool and one for the vac. When the box senses a current draw on the tool, it automatically switches on the vac. Obviously this could be used to auto-switch other tools (lights, power feeders, fume extractors, etc.).

Remembering Dad

I’ve been getting some really wonderful responses to my call for memorable shop tales and favorite reminiscences (for possible inclusion of Vol 2 of my Tips book). Here’s the first one I received, from reader Steve Stroh. If you have a story, email me!

My Dad had jars of misc. bolts, screws, etc. He always had a set of old newspapers tucked into the corner of the workbench. When he needed a bolt or screw or nut, he got the appropriate jar down, unfolded the newspaper, and poured out the jar onto the newspaper. After he found the hardware he needed, he just folded the newspaper up and poured the contents back into the jar. It was very efficient and neat.

My favorite workshop memory from my childhood was the summer we built a small, 2-story playhouse for the back yard. My late Dad was the manager, but us boys did all the work, sawing, nailing, etc. We did it during that summer’s evenings. Dad took advantage of being in the garage to smoke a cigar, and his venerable old Zenith tube radio (that he’d had since he was a kid) was on the corner of the workbench usually playing the Detroit Tigers baseball game (we lived about two hours away from Detroit, and were within perfect reception range of WJR AM 760, a powerhouse AM broadcaster in Detroit. Dad got to teach us basic woodworking – we used hand saws mostly, though he did teach us how to use the table saw), drilling (manual and electric). It was a lot of fun, and I can still picture it as I write this to you.

My favorite current workshop memory is that when we moved into our previous house, my late Father In Law found a stash of solid core doors that had been left behind in the basement. He used one of them to make a workbench, using some old steel workbench legs that he had stashed away. It was sturdy, and serviceable, and even though now, a couple of decades later, I could easily afford a bigger and better workbench, I can’t bear to part with it. I think of him every time I use it.

I passed that basic familiarity with tools and techniques to my daughter, who isn’t afraid to tackle most small projects. She’s handier with tools than most of her friends, and especially her new boyfriend, which he takes in good grace and lets her teach him.

Shop Talk

Reader Gary responded to my piece in issue 67 about the nobility of dirty hands:

Reader Gary responded to my piece in issue 67 about the nobility of dirty hands:

My father was a professor of Entomology for his entire career. His hobby was graphic arts. My mother was a crackpot typist in a college town. Typing and printing theses grew into a small family print shop. My father would teach and research during the day and run offset presses in the evenings. Needless to say, every crevice in his hands were ingrained with ink, mostly black. He bought Cornhuskers hand cleanser/lotion by the gallon.

(Gareth’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. To receive the newsletter a week early, sign up here. — editors)