Making Your Own Steel Boxes

Gareth's Tips, Tools, and Shop Tales - Issue #142

Gareth’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. To receive the newsletter a week early, sign up here.

Happy New Year to you all and thanks so much for your tremendous support and good will throughout the year. It means a lot.

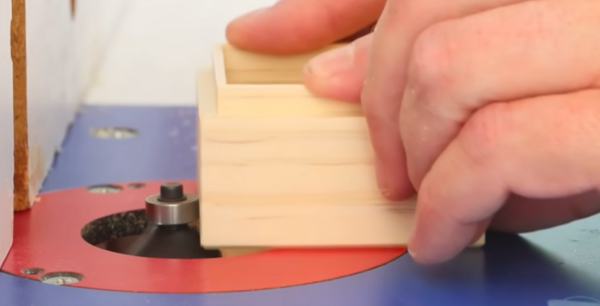

Making Your Own Steel Boxes

Metal boxes are so handy in the workshop. Image how cool it would be to make your own at whatever sizes you desire. In this Pask Makes video, he fashions metal boxes using a jig that he made. No special bending equipment required. To seal them up, you do need to weld, although, as he points out, you could easily make corner brackets and simply rivet them together.

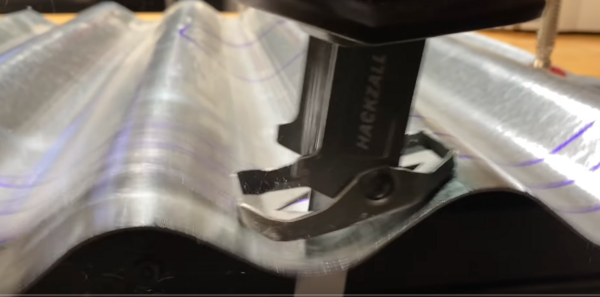

Ask Gar: Cutting Sheet Metal

Reader Martin asks me:

I’m interested in lightweight sheet metal cutting. I have tin snips but they have their limits. I know about pneumatic cutters but that’s overkill for my application. I’ve recently seen advertisements for something that connects to a power drill to cut sheet metal. Do you know about these?

There’s a reason This Old Tony refers to tin/aviation snips as “hand cramps.” The device you’re talking about is something like the Turbo Shear. I have no experience with this tool, but I’ve seen lots of video of it in action, and it looks useful if you have a lot of sheet to cut. If other readers have used this drill-attachment shear, please chime in.

There are many other options. This Farmer Tyler video shows three: A plasma cutter (which would be overkill for light material), an angle grinder, and a jigsaw (with a metal-cutting blade). You can also use a reciprocating saw with a metal blade. Then there are manual nibblers (for light-gauge metal).

BTW: Ron Covell has a great video on how to properly use aviation snips (which would make somewhat easier work than straight-pattern tin snips).

Shop Safety Basics

Woodworker and YouTuber, Steve Ramsey, offers a really great guide to shop safety basics in this video. Amongst the common advice about wearing eye, hearing, and breathing protection, and ensuring adequate ventilation, he presents some great “meta” safety advice. While these tips are directed at woodworkers, most of them apply to all types of shop safety.

* If an operation doesn’t feel right in your gut, it’s probably not. Think it through carefully. Consult the manual that came with the tool. Do a Google/YouTube search. Practice it with the machine turned off.

* Understand what the tool is actually doing; how it works. This goes a long way toward understanding what might do wrong and how to react if it does.

* Bad shop lighting, bad. The better you can see what you’re doing, the better the chances of doing it safely.

* Always keep your cellphone handy, in case of an accident.

* Be careful when doing repetitive tasks or tasks that you’ve done hundreds of time before. Lack of focus and complacency are dangerous. It can be helpful just to remind yourself before doing something repetitive that you’re about to do something repetitive and are therefore at higher risk of injury.

* And, one of the all-time best pieces of advice (what I call “The Kenny Rogers Rule”), knowing when something is not working and when it’s time to take a break, take a walk, grab a snack, etc. (Sayeth Kenny: “You got to know when to hold ‘em, know when to fold ’em. Know when to walk away and know when to run.”).

TOYS! Enamel Shop Trays

I recently “borrowed” an enamel tray from my wife’s art studio and I’m not giving it back (sorry, hon). I’ve been using it for things like parts cleaning and de-rusting. Above are two combination squares I was recently given. They were extremely rusty, but not so after a few Evapo-Rust soaks and wire-brush treatments in the tray.

The Duh Dept: Don’t Put Your Trash Cans Over the Edges of Your Worktable

It should go without saying, but I’ve made this mistake myself, lost items, and suspect they got knocked into the trash (I blame the cat). Put your cans well under your work surfaces or well away from them.

Systems Are Not Panaceas

I can’t find the video any more, but there’s a funny moment in an Adam Savage video from this year where he goes to apply one of his own shop rules and fails, on camera. The rule (which I’ve published several times) is about storing unique/specialty items that don’t have an obvious home. The idea is to go with the very first place that springs to mind when you think “Where should I store this tool?” It’s a great idea (‘cause that first thought is likely to come to mind when you need the item again). But it doesn’t always work, as Adam goes to find a special tool and can’t remember what his first storage thought was.

The cyberneticist Gregory Bateson famously said: “Always tie your ideas with slipknots.” Work systems are ideas that should be similarly tied. It’s great to think through the systems of your shop, tweak your workflow, and apply the wise thinking of others (e.g. Savage’s First Order Retrievability), but don’t kid yourself that these ideas will apply 100% of the time or in all situations.

Maker Slang

Technical terms, jargon, and slang from the realms of making.

Chase – In construction, a channel inside the walls of a building or a conduit outside of it used to protect and deliver wiring and pipes for plumbing, electrical, and other services.

Nadiral shading – Dark shading of an object from the bottom up. The opposite of zenithal shading, which is the light-shading of an object from the top down. Both techniques are used a lot in miniature painting.

Premature sheen – Term used by architect Rem Koolhaus to describe his fear that new technologies often make things look slicker, better designed, and more well thought out than they really are.

Toothing up – (or “toothing”) – Roughing up a surface to add texture/bite so that a paint or other finish will have more material to grab on to.

Notable Quotables

“You can never have enough woodworkers telling you you can never have enough clamps” – Dave Picciuto