Five Ways to Remove Bubbles from Epoxy Resin

Gareth's Tips, Tools, and Shop Tales - Issue #48

In the latest issue of HackSpace (#31), I have a piece on “Maker Math” (page 78), with formulae, calculation short-cuts, ways of estimating jobs and project costs, and more. Free PDF.

***

Tell me an inspiring shop tale.

Five Ways to Remove Bubbles from Epoxy Resin

Bubble, bubble, toil and trouble.

In this video on BuzzingFish, they run through five ways to remove those pesky air bubbles out of epoxy resin used in casting. Spoliers: 1) Wait for them to work themselves out (but before the resin sets), 2) use hot water, 3) use a heated coaster, 4) use a lighter or heat gun, or 5) use a vacuum pump.

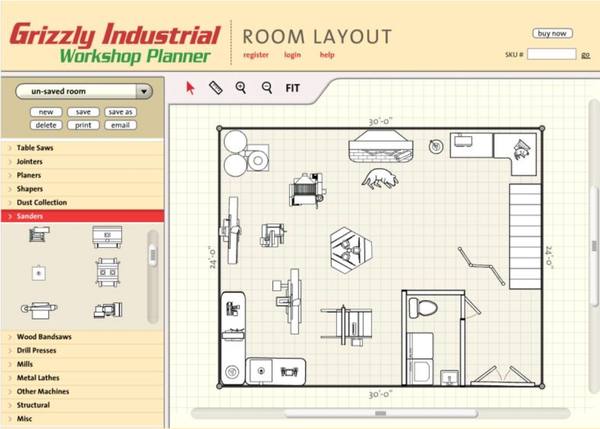

Workshop Planning Tool

Easy-to-use shop layout tool

In my piece on Better Humans, about setting up a home “makerspace,” I recommended Grizzly’s workshop planning app. I still haven’t found an easier shop layout planning tool. If you have, tell me about it.

3D-Printed Hex Bit Organizer

I need this in my life.

I love this 3D printed organizer for hex bits, available on Thingiverse. Spotted by Eric Kaplan.

Spaghetti Lighters?

![Gotta light? [Image via AcmeTools.com]](https://tkdev.kk.org/cooltools/files/2020/06/spaghettilighter.png)

Gotta light? [Image via AcmeTools.com]

I’d forgotten about this little trick. You may have, too. If you need to light a pilot, candle, or a grill where a regular match won’t reach, fire up a piece of dry spaghetti. Works like a charm. [Via AcmeTools’ Instagram page.]

Adam Savage Brings His EDC to His FOR

Getting up close and person with your most oft-needed tools.

Since we’ve been talking about “maker sartorial” here in the newsletter, I thought I’d include this Adam Savage video (by way of Donald Bell’s Maker Update). In my book, Tips and Tales from the Workshop, I talked about Adam’s concept of “first order retrievability” (FOR), which is basically the idea of having a fluid, mobile workspace (casters, lots of casters) which allows the tools you need most to be closest to you during a project. In this video, Adam talks about an old apron he’s been wearing again to bring his every day carry (EDC) onto his actual person. If these are the tools you need most often (pencils, calipers, rulers, markers, cutters, etc.), then why not get them as close to the work as possible–wear them!

Wall-Mounted Thread Checker

One-handed thread-checking with this wall-mounted reference.

In this latest Cool Tools video, Sean Ragan looks at the wall-mounted version of the highly-recommended thread checker. Jordan Bunker had previously recommended the cable-mounted thread checker in a previous CT video.

Shop Talk

On the Cool Tools website, reader KokoTheTalkingApe shared this reaction to my inclusion of Bolt Depot’s PDF reference charts in issue 46:

I’m kind of surprised, but some of the Bolt Depot’s chart is wrong, at least where it talks about “stripping” and “cam-out.” It says Phillips and slot-head are prone to “cam-out (stripping),” implying the two are the same. Then it says the hex socket are also “prone to cam-out.”

Cam-out and stripping are not the same. “Cam-out” is where the bit is driven out of the fastener head, because the hole, bit, or both, are slightly wedge-shaped. “Stripping” is where the bit damages the head to the point that the fastener is difficult or impossible to remove.

So yes, Phillips and slot head are prone to cam-out, and sometimes that can cause stripping (though not always.) Hex sockets are easy to strip, but they aren’t prone to cam-out. Both the bit and the hole extend vertically into the fastener head, so there is no force pushing the bit out.

Otherwise, that chart looks handy.

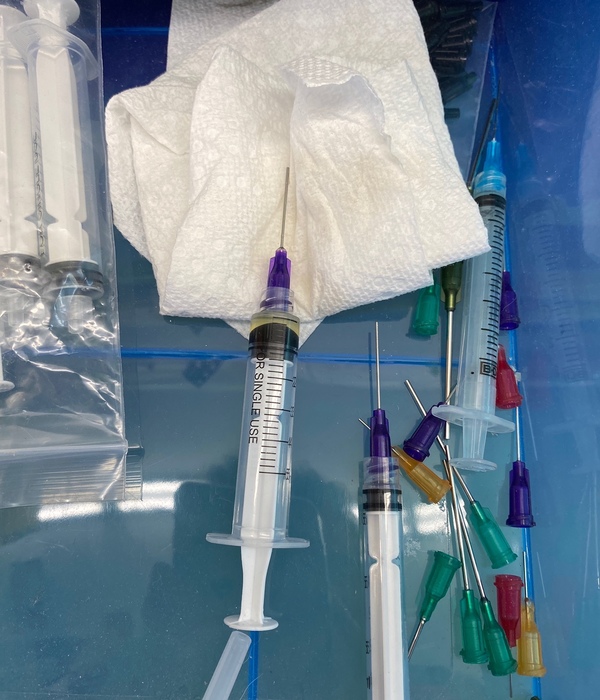

In response to the item on precision oilers in the last issue, my friend, artist Dave Mordini, sent me this image. It’s a good reminder that syringes are great to have around the shop for applying all sorts of glues, lubricants, and other thin liquids into tight or hard to reach places. These are the syringes that Dave uses.

06/4/20(Gareth’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. To receive the newsletter a week early, sign up here. — editors)