Restoring and Re-Creating an “Intimate Contact” Vise

Gareth's Tips, Tools, and Shop Tales - Issue #94

[Welcome to a surprise (to you and me both) weekend edition, brought to you by a newsletter app hiccup that caused me to lose a bunch of content on Friday.]

***

I hope you’re all having a good summer. If you’re working on any fun projects, I’d love to see them. I may share some with the class.

***

How many people were actually participating in the Molding and Casting Skill Set series? I will be going back to that ASAP, but I wanted to get some idea of how many people were actually following along. Please let me know.

Restoring and Re-Creating an “Intimate Contact” Vise

It may sound like something from an entirely different realm of human interaction, but in this Hand Tool Rescue video, Eric restores a rare 1913 vise for “obtaining intimate contact with, engaging, clamping bodies of any shape” [Patent here]. Eric calls it a “fractal vise.” Whatever you call it, it’s really a cool gadget and his restoration is fascinating to watch.

And if you look at this device and pine over the fact that this tech never caught on, fear thee not. By way of Maker Update comes news of a 3D printable version of the vise, created by Chris Borge, inspired by Eric’s video.

Using Surface-Mount Components in Through-Hole Circuits

This Twitter edition of Collin’s Lab Notes demonstrates a brilliant idea for adapting surface-mount (SMT) components for use on a breadboard or other through-hole circuit using a couple of header pins to hold the soldered SMT component so that it can plug into a breadboard or other through-hole circuit.

Surface mount meets through hole courtesy of a few header pins #adafruit #collinslabnotes

Shop tack flux at Adafruit:https://t.co/QWeqhq6yDG pic.twitter.com/99dEPnyQNy— adafruit industries (@adafruit) July 23, 2021

Removing a Splinter in a Pinch

Got a nasty splinter and are without tweezers? The Acme Tools Instagram page has this suggestion: “Simply use three washers, as shown, to remove the little annoyance.” Seems like thinner washers would work better, but you get the idea.

Design for Disassembly (DfD)

Mark Frauenfelder posted this Core77 piece on Boing Boing about the concept and practice of DfD:

Design for Disassembly (DfD) is the straightforward design method and philosophy that ensures that all elements of a product can be disassembled for repair and for “end of life.” This allows for and encourages repairs, with the result that a product’s life cycle is prolonged; and it allows for a product to be taken apart at the end of its life so that each component can be reclaimed as a technical nutrient (i.e. recycled) or biological nutrient (i.e. composted). Among other shifts in thinking and making, this means minimizing materials, using simple mechanical fasteners instead of adhesives, clearly labeling components with their material type, and ensuring components can be disassembled with everyday tools.

When I broke the glass vessel of my French press this weekend, I ordered a replacement vessel instead of purchasing an entirely new coffee maker. This was only possible because my French press was designed so that it could be easily disassembled. On the other hand, my electric kettle has started to leak. There are no small screws for me to open it – in fact, it’s mostly glued together. This means that when I finally cave and admit that this kettle is broken, I have no way to repair it and no way to recycle its parts. In contrast to the French press, the product was not designed for disassembly. My only option is to throw it out, and to buy a new one.

Read the full article here.

Adam Savage’s Guide to Drill Bits

Adam Savage’s tool tips videos are always a treat. You get an education on the design and function of the tool, Adam’s recommendations for his favorite products in the category, and you get great stories – ‘cause tools always come with stories. In this video, Adam looks at drill bits, describes the physical science of how different bit-types cut and remove material, and he makes the case for step and Forstner bit sets (among other recommendations).

Crowdsourced Tools

A new, periodic feature where I ask YOU for tool recommendations and some collective B.S. detection.

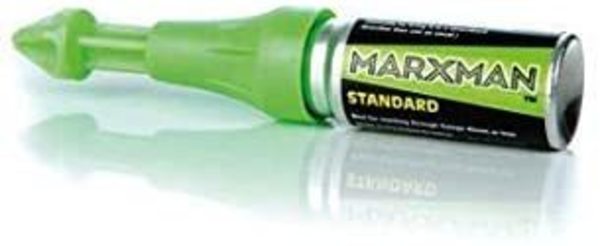

Spray chalk marking pen: I saw a video on Instagram of one of these spray chalk marking pens and thought it was an interesting idea. They’re for marking a drilling target through a deep hole. You place the barrel of the marker over the hole and press to fire. All good, but this tiny marker, a mere .6 ounces, is $18 on Amazon! Currently, I use a FastCap long-nose pattern marker for this sort of thing, but I’ve encountered several instances where it was too shallow for the holes I wanted to mark. Has anyone here tried one of these or a cheaper alternative? An airbrush blow pen?

Apartment tool kits: A gift that I’ve given several friends and relatives moving into a new home or apartment is one of those all-in-one tool kits with cheap versions of all of the essential starter tools one needs (hammer, pliers, tape measure, socket set, driver and bits, level, etc.). I’ve also put such kits together myself as gifts and but that’s a lot more expensive. Many of these kits are in the $50 price range, and I know from experience, the quality and design of the tools varies dramatically. Is there such an “apartment toolkit” you recommend?

Silicone Mixing Cups and Stirrers

Working on the Molding and Casting series reminded me how many plastic cups and wooden stirring sticks you use when working with casting rubber and resin. In this short Cool Tools video, Tyler Winegarner extols the virtues of reusable silicone cups and stirring sticks for resin work. When the waste material on the cup and stick is dry, you just peel it all off. This set of cups, sticks, and other accessories costs only $11 on Amazon.

Notable Quotables

“The top question I get asked after every video is ‘Where did you learn this stuff and how can I (or my kid) do this?’ Here’s what I say. Find a project that drives you. Seek lessons only for what is needed to finish that project. Repeat. The things I do are not taught, they are discovered.” –YouTuber Jeremy Fielding

Shop Talk

Even more moving advice from reader Mark White:

“My wife and I just moved after being in our previous home for 17 years. The best tip we got was to mark off the attached garage with masking/painters tape into areas and label with room names (living, den, etc.). As your movers/friends are bringing in the boxes, have them leave the boxes there. This method has multiple advantages such as not having to live among boxes, and if you are paying your movers/friends by the hour, this shaves off time because they don’t have to take the boxes all of the way into the house. This also allows you to unpack at your leisure and to go get what you need at any particular time and in ‘ I need this now’ order. Thanks again for a e very informative newsletter.”

***

Doug Pocius, responding to jumper wire kits:

“The 26 gauge solid copper wire used in telco cables makes dandy prototype board jumper wires, and scraps are usually free! A long time ago, I came across a 1 foot piece of 3” diameter cable in the trash with maybe 200 pairs of this wire in many different solid/stripe color codes. Never had to buy jumper kits after that. ”

***

I got a resounding yes from many readers on the superiority of Robertson/square head screws. Steve Roberts writes:

Yes on Robertson bits! I was first exposed to them when I bought a Canadian boat, and have preferred them ever since. Being able to stay locked into the head EASILY, with my Magapro multi-bit driver, is fabulous… even when I can’t see what I’m doing. I wish they would become the dominant standard.

(Gareth’s Tips, Tools, and Shop Tales is published by Cool Tools Lab. To receive the newsletter a week early, sign up here. — editors)