Sean Michael Ragan, Author and Former Editor of Make

Cool Tools Show 175: Sean Michael Ragan

Our guest this week is Sean Michael Ragan. Sean is the author of three books including The Total Inventor’s Manual, which is on sale now at Costco, Sam’s, and all major book retailers. He’s also a former editor of and longtime contributor to MAKE Magazine and MAKE online. You can find him on Amazon, Medium and Instagram.

Subscribe to the Cool Tools Show on iTunes | RSS | Transcript | Download MP3 | See all the Cool Tools Show posts on a single page

Show notes:

3M Stikit Gold Paper Sheet Roll

When I use sand paper I find it’s not very useful as just loose paper. There are a lot of clever sanding blocks out there and sanding solutions but 3M, as far as I know, is the originator of this idea where you just sell sand paper on a roll and you put a peel and stick backing on it, which if you’ve ever fiddled about trying to attach sandpaper to a wooden block for sanding or to a piece of glass or a surface plate for lapping, is obviously a smart idea.

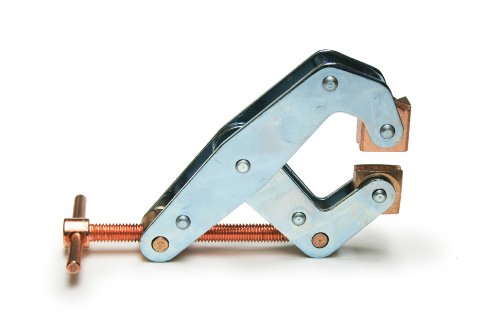

Kant Twist Clamps

These work kind of like C-clamps, except better in almost every way. I say “almost” because these are a lot more expensive than C-clamps. But the advantages I think are worth it: The cantilever mechanism means the screw you turn to tighten the thing is actually perpendicular to the applied clamping force, instead of directly in line with it. The jaws sort of lever sideways to give you more mechanical advantage than you’d get from turning the same size C-clamp handle. So you can clamp harder without working as hard to do it. The gripping pads, or jaws or whatever, are plated in copper to keep them from marring up your work, and because the screw doesn’t directly impinge on them they can rotate to align with the faces of your part. Also you can spin them around to one of several different gripping faces before you tighten the clamp down — one’s smooth, one has grooves, stuff like that.

Noga NF61003 Dial Indicator Holder w/Magnetic Base

If you want to do any kind of precision work with a drill press, lathe, mill or other machine tool, you need to have a dial indicator and a way to position it where you need it. Thing is, a dial indicator is really not that complicated from an engineering perspective, and for most applications all you’re doing is trying to minimize movement of the needle along a toolpath or around a cutting axis. So a cheap import one works fine. It’s better to have a good one, but if you’ve only got so much money to spend, it makes more sense to buy other stuff first. So here’s a case where it actually makes sense to spend more money on the mount for the instrument than on the instrument itself. These arms come on a switchable magnetic base so you can stick them to ferrous metal surfaces and the Nogas in particular are just awesome when it comes to being able to quickly position them where you want them and lock them down. With a Noga, you can basically loosen one knob, pull the end of the thing where you want it to be, and tighten the knob back down, and the whole arm locks up rigid. So it’s quick and reliable and a real pleasure to use.

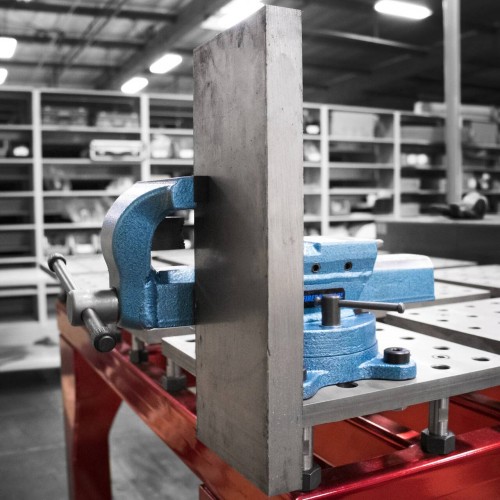

Fireball Forged Bench Vise ($120)

I picked this vise for lots of reasons: First of all, it’s the only commercial vise I know of that can be ordered with solid copper jaws. Usually if you want a set of copper jaws, you have to make your own. And copper jaws are so much better for most things, and in so many ways, than the hardened steel jaws that most vises ship with. A) Copper’s soft and so it doesn’t leave marks or scratches on stuff, even if you gronk down really hard on it; B) copper is malleable, so it actually conforms a bit when you grab down on a part and grips it better than hard steel, so its less likely to slip; C) copper is a great conductor of heat, so if you’re using a torch or a soldering iron on a part you’ve got clamped in the vise, copper jaws will help keep it cool. D); finally, copper is a great conductor of electricity, so if you’re doing some kind of arc welding process on something you’ve got clamped in the vise you can count on the copper jaws to make good electrical contact with it for your ground electrode. Apart from the jaws, this is just a badass vise in general: It’s forged instead of cast, so it’s stronger, it’s got a separate set of round pipe jaws underneath the flat jaws. It’s got a little anvil on it. And it’s got a bolt hole pattern in the base that fits the fixture holes that are standard on BuildPro welding table fixtures, which means you can mount it on your table quickly and take it off just as quickly and count on it to solid in between. Plus I think it’s really pretty, too. I like the kind of crystal blue hammertone paint a lot. Finally, Fireball tools is a cool little US company owned and operated by a maker in Washington state. His name’s Jason Marburger and he’s got a really interesting YouTube channel.

Also mentioned:

I just finished up my third book, which isn’t out yet, but hopefully will be soon. It’s called “Breadboard ‘Bots” and it’s a series of robotics projects that can be put together without soldering or programming anything by building modular circuits on those little mini breadboards and then interconnecting them mechanically and electrically in various ways. If you all remember the whole BEAM robotics thing, the designs are a lot like that, except without all the fancy freeform soldering. I always liked BEAM because I like the game of trying to get these little robots to have the most complicated possible behaviors using just, you know, sense-and-respond kind of analog electronics and clever mechanical design instead of programming a microcontroller or microprocessor. So that’s not out yet, but it’s done, and I’m kind of casting about for my next project at the moment. I used to have an Etsy store that was pretty successful and I miss doing that, so I may try to fire it up again.