Spencer Wright, Founder of The Prepared

Cool Tools Show 268: Spencer Wright

Our guest this week is Spencer Wright. Spencer is the founder of theprepared.org, where he edits a widely read newsletter about engineering, manufacturing, and other meaningful work in the physical world. His career has spanned construction project management, bicycle framebuilding, consumer electronics, and generative design software. He also co-organizes the New York Hardware Meetup and spends a lot of time trying to get his four-year-old daughter excited about hanging out in his Brooklyn workshop. You can find Spencer on Twitter and Instagram @pencerw.

Subscribe to the Cool Tools Show on iTunes | RSS | Transcript | See all the Cool Tools Show posts on a single page

Show notes:

Cord reels & overhead power

We’re in an old, old, industrial building in Brooklyn and it has these great high ceilings. And the ceiling is all concrete, which kind of has some downsides, but has some upsides. And in this case, we mounted all of this conduit and these receptacles right to the ceiling and then hung these overhead cord reels, with these retractable extension cords right next to them. The result is that whenever you want power anywhere in the shop, we laid these things out on a grid. And so you just reach up and grab the closest extension cord from right above head and pull it down to you. The cord reels themselves, they’re about maybe a foot in diameter. They hang from the ceiling very easily and then they have a 25 or a 30 foot extension cord coiled up inside them with a spring retract system. And the result is that you have this easy access to power anywhere in the shop and no extension cords around the ground to trip on. Even in a smaller shop, something with a roughly eight foot ceiling, you could mount them right in the corner, right where the ceiling meets the wall and you have the same effect. Where they’re out of the way. You’re not walking into them all the time and they’re easy to reach. And again, your power is all above you and so whenever you do need an extension cord, you’re not tripping over it.

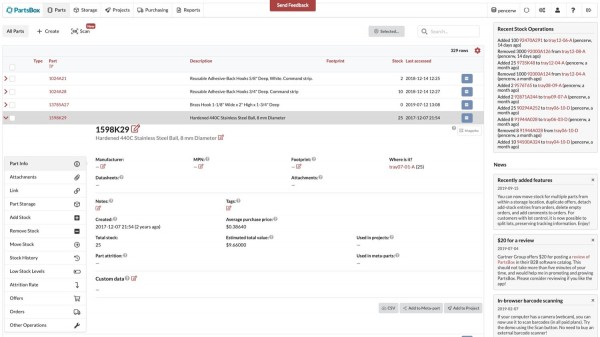

Partsbox

PartsBox is a digital way of managing all of the inventory of everything you keep in your shop. Basically, you know when you get a small parts cabinet, that have either a bunch of little drawers or one large drawer with a bunch of sub-compartments. And usually they give you a booklet or a tape of these little stickers or cards that you are supposed to write the part number on or the specifications and then stick it to that drawer. PartsBox is a digital replacement for all of that. It’s a website and you create your own catalog of parts and then tell PartsBox where each part is stored, how many you have there, what they cost, so on and so forth. You go to your physical part cabinet and you just name every single compartment in it. And PartsBox has easy ways to do this where you just kind of create a grid and you say, you have columns and rows. And so this is bin A4 or whatever it is. And then you add whatever parts that you have in your inventory into PartsBox and assign them to that storage location. I name all my parts that McMaster-Carr number or whatever it is and then add enough detail so that PartsBox’s search system can easily find what I might be looking for. For instance, I use mostly metric fasteners and if I’m working on a project, I need an M5 socket head cap screw, I’ll go to PartsBox. I won’t look at my physical parts storage at all. I go to PartsBox first, I search M5 socket or something like that and up come the 20 different parts that meet that description. And if I click on them, then it tells me what storage location to go to to look for them.

Paulk style workbenches

I built a Paulk workbench. The Paulk workbench design is something that’s distributed by this guy, Ron Paulk, who is a YouTube and internet personality. He’s a woodworker who has created this design and sells plans for it. And the idea is that you make it yourself. It’s a woodworking workbench that’s made primarily of plywood and the workbench top, instead of being a solid, like a butcher block, is a plywood box that uses what’s called a torsion box system. And so the workbench top, in my case is 200 millimeters tall and it has a top surface and a bottom surface and then some ribs and sides to hold them together. And the result is that you have this great built-in storage area in your workbench top, you have kind of a shelf, where you can keep commonly used tools. And then the standard Paulk workbench uses plywood saw horses for the base. I actually used this industrial framing system called Flexpipe, which is a kind of a steel pipe system to build this substructure. But then the idea with the workbench is that you use it to mount both your table saw and a router table as well. And it becomes kind of the central workstation for your entire wood shop. Geared mostly towards folks who are making things out of plywood.

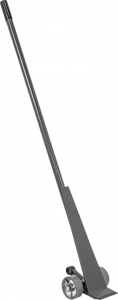

A Johnson bar

My last pick is a Johnson Bar. Johnson bar is kind of like a cross between a crowbar and a hand truck. It’s this big piece of steel or wood, usually about six feet long and one end there’s a handle and the other end, there are two little wheels and a little lip. A pry lip that you can use to lift really heavy things off the ground. They’re used mostly to move heavy machinery and they can lift up to 5,000 pounds pretty easily just with one person. They only lift them a couple of inches, but they’re kind of magical. It’s kind of like an Egyptian way of moving heavy things around where you have this really, really, really long lever and are able to scoot something that’s very heavy, a very small distance. And the beauty of owning the Johnson bar is that they enable you to take unloved, heavy equipment off other people’s hands. There are a lot of milling machines and lathes out there that someone bought decades ago and they’ve been sitting on a garage floor ever since. And they decline in value, partly because they’re just difficult to move. Now you’re not going to use a Johnson bar to move something down the street, let alone to a different city or something like that. But you can use it to just get a heavy item up onto a dolly or a hand truck or a pallet jack. And it really is just an incredible super power to be able to lift this heavy thing just a couple of inches and then actually move it.

About The Prepared:

The Prepared is a weekly newsletter that I word as meaningful work in the physical world because, it’s partly about manufacturing, partly about logistics, partly about construction — kind of the areas of my career that I’ve worked in. And it’s divided up into some industry news, some just engineering factoids and then the random kind of interview or plenty of manufacturing videos as well. My belief is fundamentally that being a generalist helps you make good decisions. And in addition, it’s personally enriching to be aware of things kind of in the adjacent possible. Some of my favorite conversations with engineers have been folks who work in industries that I would never consider working in. And The Prepared is kind of meant to treat all those things with at minimum, curiosity and ideally with some degree of respect. There are plenty of really interesting engineering topics happening in oil and gas and aviation and also in single family home construction. And my belief is that you don’t have to agree with them, you don’t have to study them at much length, but being aware of them and at least considering what their implications are, can make you better at the things that you do, whether or not you work in the physical engineering world.

We have hired professional editors to help create our weekly podcasts and video reviews. Please consider supporting us on Patreon. We have great rewards for people who contribute! If you would like to make a one-time donation, you can do so using this link: https://paypal.me/cooltools.– MF

03/5/21